Didn't expect the plumbing to take all day :[

Heres the photos as promised.

Painted background, stole monkiboys plasti dip idea. Unlike his fancy self, I like it :)

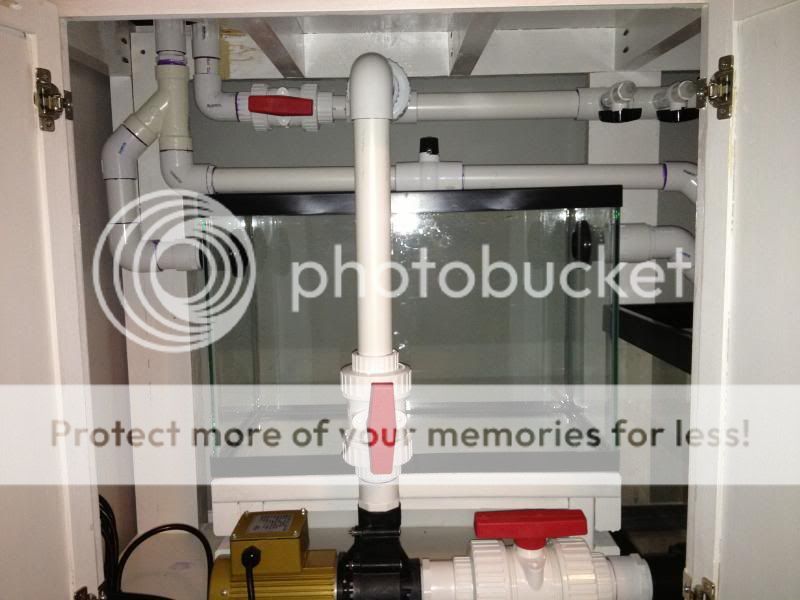

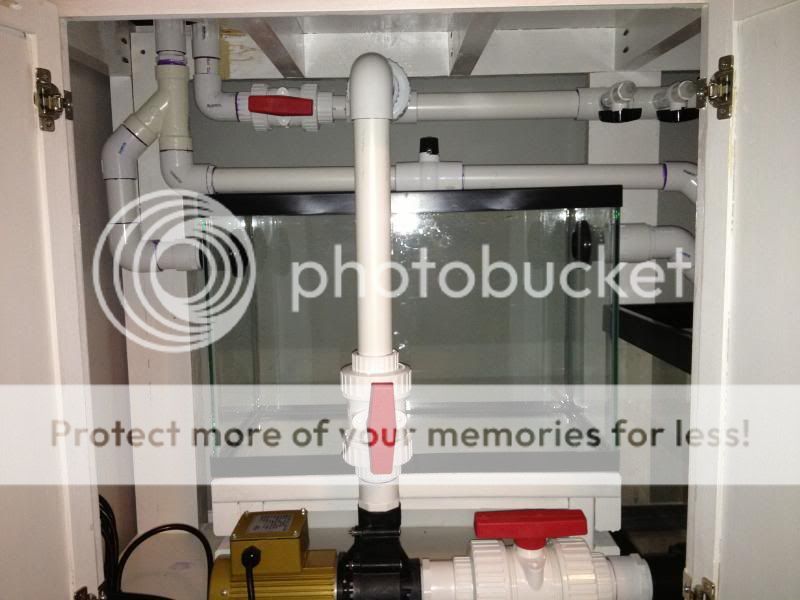

And here is the sump/fuge with plumbing. Below is the 20gallon high that will be used for the fuge. The left overflow is T'd off to have 2 separate exits, one from the fuge and one from the DT.

You can see the drains here as well. Also you'll notice the return; I have 4 sections that will feed gfo, carbon, calcium reactor, and the last one is for water changes.

the drains to sump

the first chamber on the right is where the drains run. They will then spill over the frontside of that section into my 5 gallon frag area. I will hang a kessil pendant over this when the time is right and frags are in it. Water then flows over the backside into the skimmer area

skimmer section and bubble trap before return

feeds again with ball valves

and "full under tank shot" I guess is the best thing to call this haha

the remaining equipment will be set up in the left and right side cabinets. One will hold my ATO and supplies while they other will hold the calcium reactor, tank, and monitors/electrical