BL1

.............

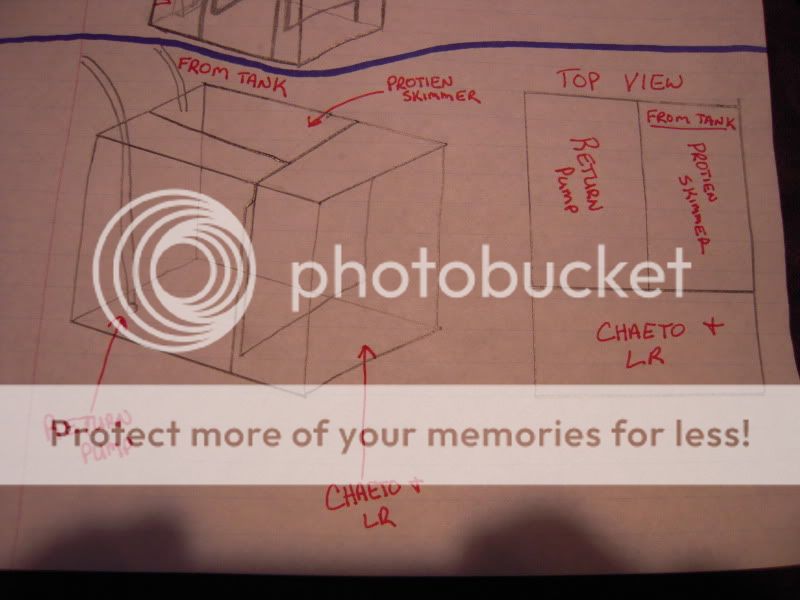

I'm trying to make some drawings of possible refug ideas but, I need to know how to set it up ... In he baffles do you want the chaeto to come first so it's getting all the nutirents from the tank. Or do you want the chaeto after the skimmer so that the pods in the chaeto aren't going through the skimmer and getting killed?

And I don't know the model offhand, I'll have to look later but, are the 266gph accella pumps that come with the nano cube strong enough to return the water back into the aquarium from the stand, or will I need to upgrade the pump too?

And I don't know the model offhand, I'll have to look later but, are the 266gph accella pumps that come with the nano cube strong enough to return the water back into the aquarium from the stand, or will I need to upgrade the pump too?