RockStacker

Reefing newb

Right now it is just an empty glass tank, and a lot of planning and window shopping.

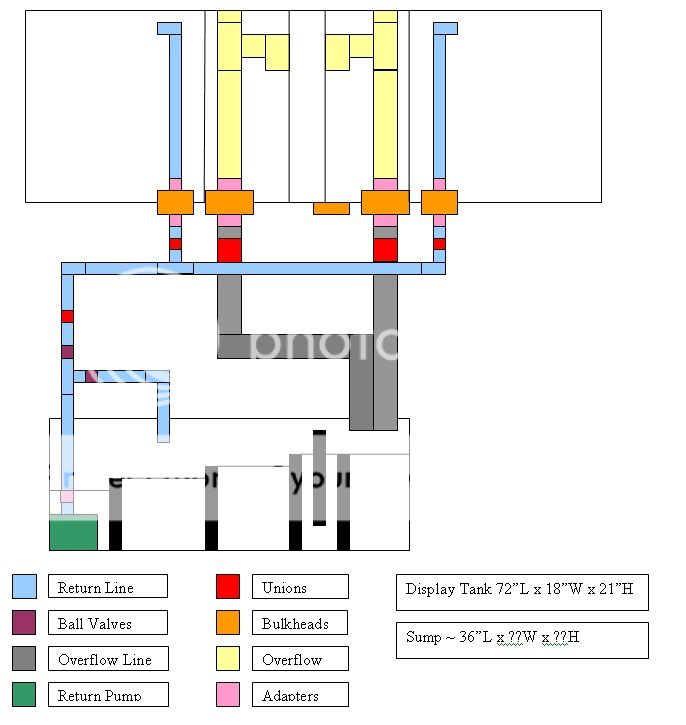

Since the tank is already pre-drilled at the bottom, I am planning the following layout.

Of course the plan can still change depending on what my planning and research turns up.

Return lines will be 3/4" tubes. Overflow lines will be 2" tubes.

I was also contemplating using one of the overflow lines to feed a "Chaeto Channel" above the sump which will then overflow into the sump.

If anyone knows a good place to buy Schedule 80 stuff other than BRS please let me know. I am price shopping right now for the materials.

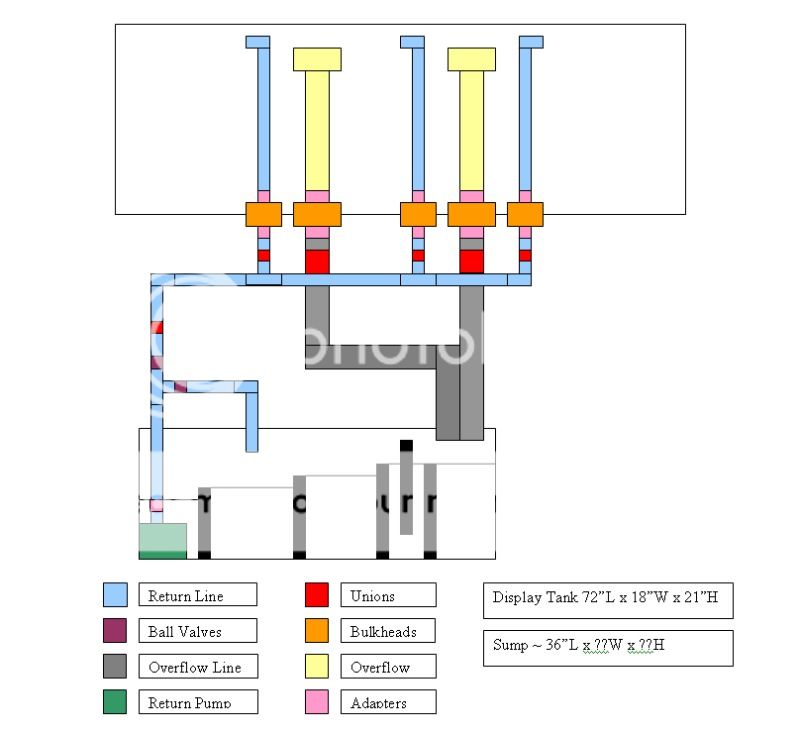

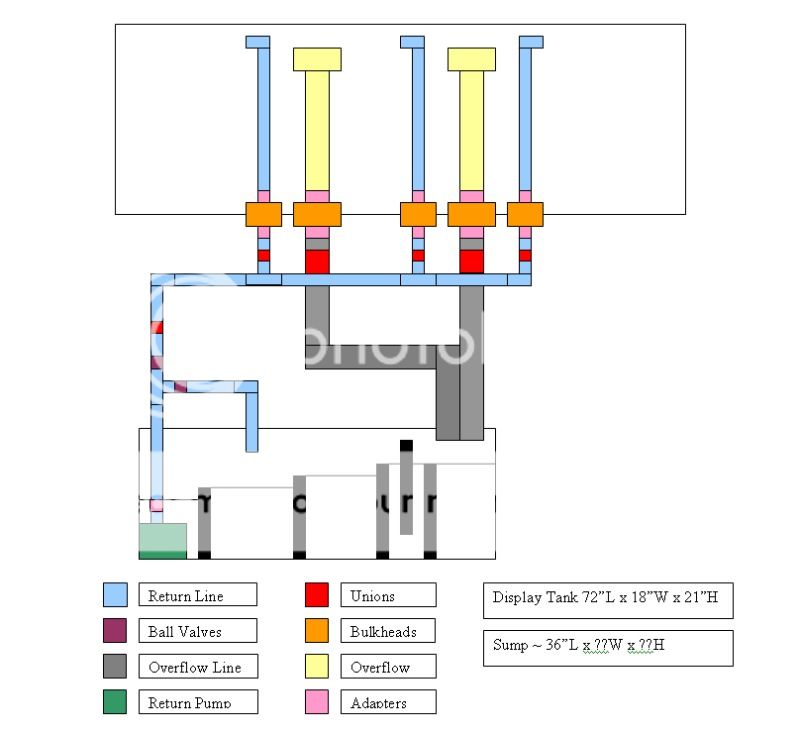

Since the tank is already pre-drilled at the bottom, I am planning the following layout.

Of course the plan can still change depending on what my planning and research turns up.

Return lines will be 3/4" tubes. Overflow lines will be 2" tubes.

I was also contemplating using one of the overflow lines to feed a "Chaeto Channel" above the sump which will then overflow into the sump.

If anyone knows a good place to buy Schedule 80 stuff other than BRS please let me know. I am price shopping right now for the materials.