Doc

I don't work for anybody

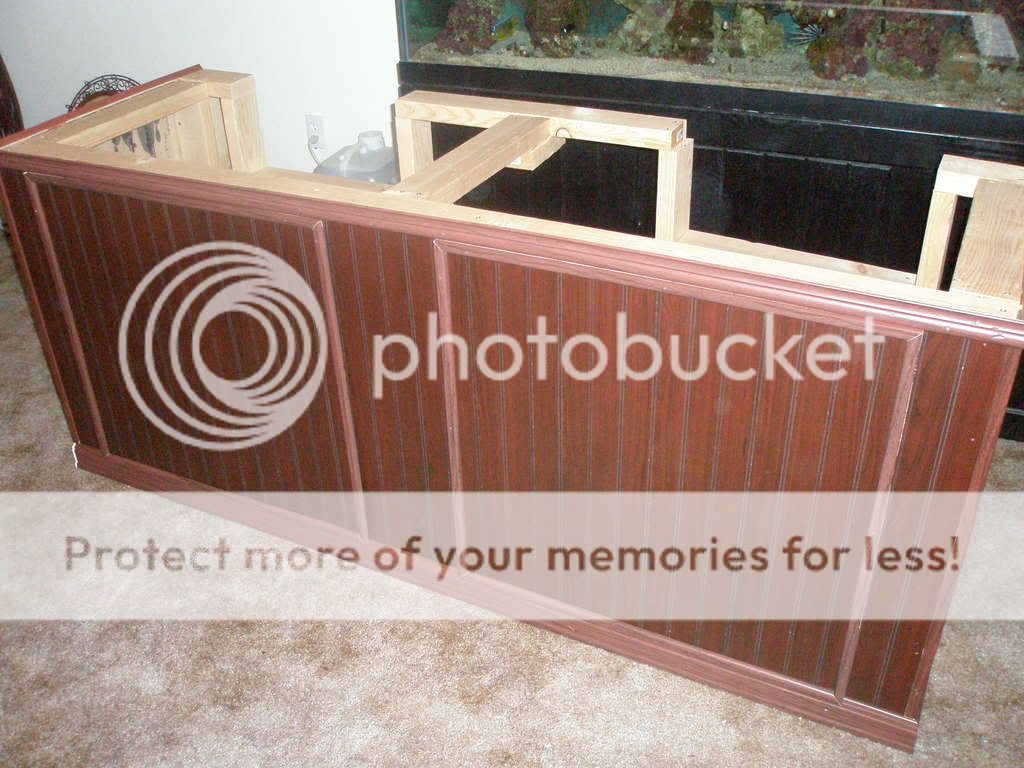

aaaaaarrrrrgh!!!!!!! off by 2 centimeters!!!!!! WHY??? Why must the gods of hardware and carpentry hate me so!!!! Dammit! I f&%king hate DIY projects!!! what the F$%K is wrong with me. Why not shell out the extra $750 for the stand, noooooooooo, I have to try to be F*&king Bob Villa.....:frustrat:

Now then, I feel better. I will get back to my piece of :pooh: stand. I will have to learn to cope with "good enough".

-Doc

Now then, I feel better. I will get back to my piece of :pooh: stand. I will have to learn to cope with "good enough".

-Doc